Quality

The production process enhances the craftsmanship and supports it with technology, to guarantee short delivery times.

The company's sophisticated management system ensures precision and flexibility. Behind the machines however there are people: thanks to their contribution GAP DESIGNS products always distinguish themselves for their creative and unique features. Teak wood, high quality fabrics and exclusive processing: a careful selection of the materials is the fundamental ingredient of our furniture products. GAP DESIGNS is proud of its solidity as a company: customers, employees and suppliers have always taken part in the development of the brand, often with an exclusive relationship. Its history, products, quality and solidity make GAP DESIGNS a serious and reliable company.

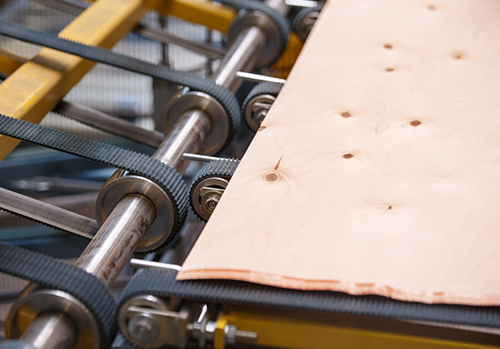

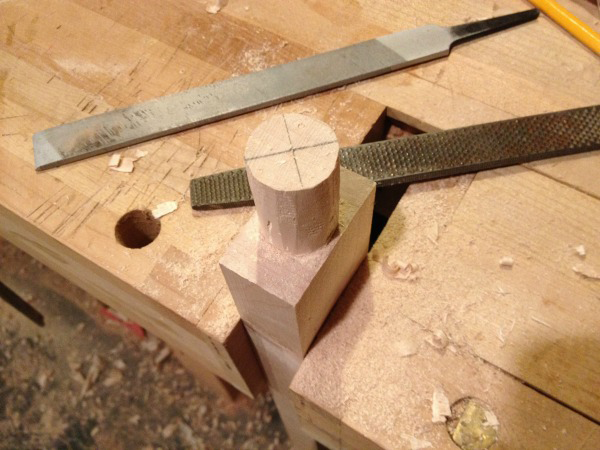

Tenoning And Drilling

In this phase the heads of the up- rights and the transoms are processed to create tenons which when duly glued and correctly fitted are used to loin the various parts during the assembly phase. These process- es are fundamental for product sta- bility and to produce a long lasting solid structure.

Pre- assembly

The parts that make up the back or the front part of the frame are assembled in this phase. The use of the correct amount of glue is partic- ularly important in this phase; an insufficient amount of glue would result in an unstable product while an excessive amount would lead to an unaesthetic result.

Polishing And Lacquering

Polishing is a necessary operation in order to preserve the wood; lacquering entails the homogenous application, on the entire surface of the product, of "coats" of varnish in the required colour to give luminosity and add decorative effects to the product. There are different types of lacquering processes, from the classic one that uses nitro-based products to the ecological one that uses water-based products, up to the application of precious silver or gold leaf. Lacquering requires great skill to avoid undulations or other unpleasant effects on the product surface.